Acucut A12 Classifier

The Acucut A12 classifier utilizes dual stage operating controls to ensure sharp cuts and narrow band particle size distributions. This permits control of maximum and minimum particle size diameters with unparalleled accuracy. Precise control of rotor speed and air flow means that Acucut classifiers will produce the same sharp cuts and narrow band particle size distributions each and every time.

The Acucut A12 classifier utilizes dual stage operating controls to ensure sharp cuts and narrow band particle size distributions. This permits control of maximum and minimum particle size diameters with unparalleled accuracy. Precise control of rotor speed and air flow means that Acucut classifiers will produce the same sharp cuts and narrow band particle size distributions each and every time.

The Acucut A-12 classifier uses a high speed, high energy air classification principle to disperse and separate ultrafine powders. The Acucut processes 0.5 to 50 micron powder fractions at feed rates up to 3,500 pounds per hour, accurately, reproducibly, and efficiently.

Alpine 1-40 MZM Multi-Plex "Zig-Zag" Classifier

The Hosokawa Alpine 1-40 MZM "Zig-Zag" classifier is the ideal alternative to sieves. Separation range is approximately .1 mm / 6 mm with a throughput that can range between 10 / 100 kg/hr depending upon the material and the separation requirements.

The Hosokawa Alpine 1-40 MZM "Zig-Zag" classifier is the ideal alternative to sieves. Separation range is approximately .1 mm / 6 mm with a throughput that can range between 10 / 100 kg/hr depending upon the material and the separation requirements.

The 1-40 MZM is ideally suitable for separating leaves and stalks in the production of leaf drugs and herbal teas as well as the manufacture of protein concentrates or to separate the shells and pods from precrushed or disintegrated fruits and seeds.

Alpine 50 ATP Turboplex Classifier

The production of fine powders is becoming more and more complex because of the increasing demands made on the end product. These demands, for a great number of products, have led to an extension of the grinding process to include air classification. As a result, the ultrafine classification of powder materials is becoming a key issue. The Alpine 50 ATP Turboplex classifier is capable of many applications due to its extremely wide stepless adjustable separation range with a d97 of approximately 2 to 120 microns.

The production of fine powders is becoming more and more complex because of the increasing demands made on the end product. These demands, for a great number of products, have led to an extension of the grinding process to include air classification. As a result, the ultrafine classification of powder materials is becoming a key issue. The Alpine 50 ATP Turboplex classifier is capable of many applications due to its extremely wide stepless adjustable separation range with a d97 of approximately 2 to 120 microns.

In contrast to conventional air classifiers, the classifying wheel axis of the ATP runs horizontally, not vertically. This design feature improves wear resistance when processing highly abrasive materials, and helps to reduce the risk of deposit formation with sticky materials.

Alpine 100 Multi-Plex MZR Classifier

The Alpine 100 MZR Classifier is often used as an analytical classifier for determining particle sizes. Materials with a hardness of up to approximately Mohs harness 6 can be processed. Because of its high dispersing capabilities, the Alpine 100 MZR can also be used for analyzing materials which tend to agglomerate.

The Alpine 100 MZR Classifier is often used as an analytical classifier for determining particle sizes. Materials with a hardness of up to approximately Mohs harness 6 can be processed. Because of its high dispersing capabilities, the Alpine 100 MZR can also be used for analyzing materials which tend to agglomerate.

The Alpine 100 MZR is simple to operate; the cut point is merely dependent on the classifying wheel speed and the air volume. The supplied calibration curve, which is representative for many different materials, can be used to determine the set values for the cut point desired in each case. The Alpine 100 MZR can be easily dismantled without tools and both wet and dry cleaning of the apparatus is possible. The product contact parts are made of stainless steel or corrosion resistant aluminum alloy.

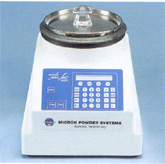

Micron Air Jet Sieve MAJS I

The Micron Air Jet Sieve utilizes a dynamic sifting principle that enhances the accuracy and reproducibility of particle size analysis. Use of this device has become a preferred method for such tasks as quality assurance of incoming raw materials and the confirmation of final product specifications.

The Micron Air Jet Sieve utilizes a dynamic sifting principle that enhances the accuracy and reproducibility of particle size analysis. Use of this device has become a preferred method for such tasks as quality assurance of incoming raw materials and the confirmation of final product specifications.

While negative pressure draws all the particles below a defined particle size down through a screen, a positive airflow is introduced upwards through a rotating wand. This airflow deagglomerates and disperses any undersized particles. Precise particle size can be quickly determined at sizes from 20 to 4,750 microns. This unique rotating wand method also eliminates the need for tapping or brushing and increases reproducibility with controlled measurements of pressure drop and duration. Additionally, the operation is quieter, cleaner, and requires less space than other types of similar analytical equipment. Where absolute reliability in determining particle size and particle size distribution is essential, the Micron Air Jet Sieve is the industry choice.

Basic System Components:

- Vacuum (4 gallon collection capacity)

- Sieve Screen Cover

- Sieve Tapping Hammer

- Sieve Brush

Developed by: JAMIR Design™

This site has been developed using 1024x768 Screen Resolution and Best Viewed in 1152x864.

This site visited: Times.